Odor reduction

Odor reduction for the industry

Due to the constant growing together of industrial and residential areas,

complaints from residents about production-related smells are increasing.

We offer

two efficient technologies for this, which, individually or in combination, deliver the best results and also protect your balance sheet.

Standard or taylor-made

Your needs determine the solution

The economical solution

Cold oxidation using ozone - Eco-Cube

Ozone is a naturally occurring strong oxidizing agent which is generated by the UV rays of our sun from the oxygen contained in the atmosphere.

Ozone can also be generated artificially using various methods. The Eco-Cube system generates ozone by using highly efficient UV lamps or ceramic plates (coronal discharge).

This system is characterized by very low operating costs, minimal maintenance and very good efficiency. Above all, it can be used very economically at low and medium odor levels.

The alternative solution

Adsorption using activated carbon

Activated carbon is a highly porous carbon that has a very large inner surface. The pollutants to be removed from an exhaust gas or a liquid are adsorbed. The substances are bound to the coal surface by "van der Waals forces". This process is reversible, which means that activated carbon can be regenerated.

Activated carbon is made from coconut shells, hard coal or wood, for example, and accordingly has different properties.

These filter systems are often used in the field of exhaust air purification to reduce medium to strong odors.

The flexible solution

Combination of both technologies

In many cases, the combination of both technologies is worthwhile. In this case, an ozone system is installed upstream of the activated carbon filter stage.

This variant significantly extends the service life of the activated carbon, which enables considerable cost savings when replacing and disposing the coal.

Another advantage is the possibility to switch flexibly between a solo operation with Eco-Cube or a combined operation with both systems. This is a way of reducing the consumption of activated carbon and saving energy, especially when the smell level fluctuates (e.g. due to process or weather conditions).

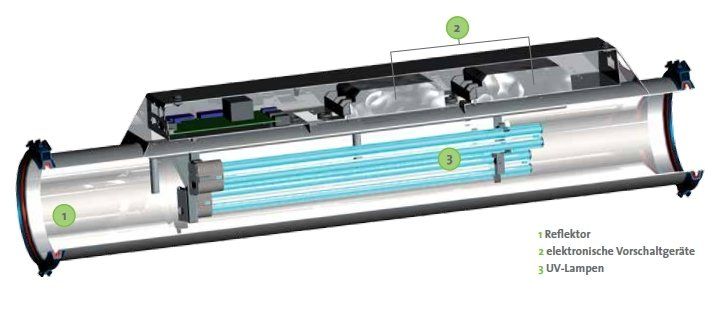

Cold oxidation using ozone - Odourtube

Operating principle

The ozone-air mixture generated in the ozone generators from the ambient air is injected into the exhaust air stream to be cleaned.

Since the ozone generators in this variant do not come into contact with the polluted exhaust air, they remain clean and the effectiveness is not reduced.

The injected ozone reacts in the exhaust air pipe/duct with the compounds to be oxidized (mostly hydrocarbons).

Benefits

- No use of chemicals and no generation of contaminated waste

- High effectiveness and constant efficiency since there is no contamination of the components

- Modular design and easy to retrofit into existing systems

- Plug & Play - works immediately

- Compact design and very low energy consumption

- Reduces not only odors but also VOC's and fat deposits

- Very low operating costs and particularly low-maintenance

Applications

Eco-Cube can be used in almost all conceivable areas where light and medium odors arise and are emitted:

- various branches of industry (e.g. plastics and food industry, etc.)

- animal husbandry

- catering and canteen kitchens

- waste treatment plants

- asphalt recycling

- to extend the service life of activated carbon

- reduce VOCs (gaseous organic compounds)

- and much more

Adsorption using activated carbon

Operating principle

Activated carbon is available in powder form, as granules or as pellets in various grain sizes. The mode of action of coal is common to all forms. We primarily use granules or pellets for exhaust air purification.

Due to the very large inner surface, pollutants can be adsorbed and bound in the fine pores. This is easily done by passing the pollutant-containing gas through a bed of activated carbon pellets, for example.

Different types of coal also have different adsorption capacities for the respective substances. This means that the coal must be replaced or reactivated at the latest when the saturation load is reached. There are various options for making the best possible use of the activated carbon's adsorption capacity.

Combination of both technologies

Get the best out of two systems

By adding ozone containing air to the activated carbon filter, the service life of the coal

can be considerably extended. Depending on the process, exhaust gas composition, amount of ozone and other factors, the service life of activated carbon can in some cases be extended by twice, thrice or more.

This has a positive effect on procurement/operating costs, disposal costs and downtimes or production interruptions.

Another option for protecting the activated carbon is by-pass operation. Odors in the exhaust air are reduced here by adding ozone (Eco-Cube system) and an activated carbon secondary filter stage is only activated in exceptional cases. This can be the case if the intensity of the odor fluctuates or the weather conditions have an influence on the emission distribution.